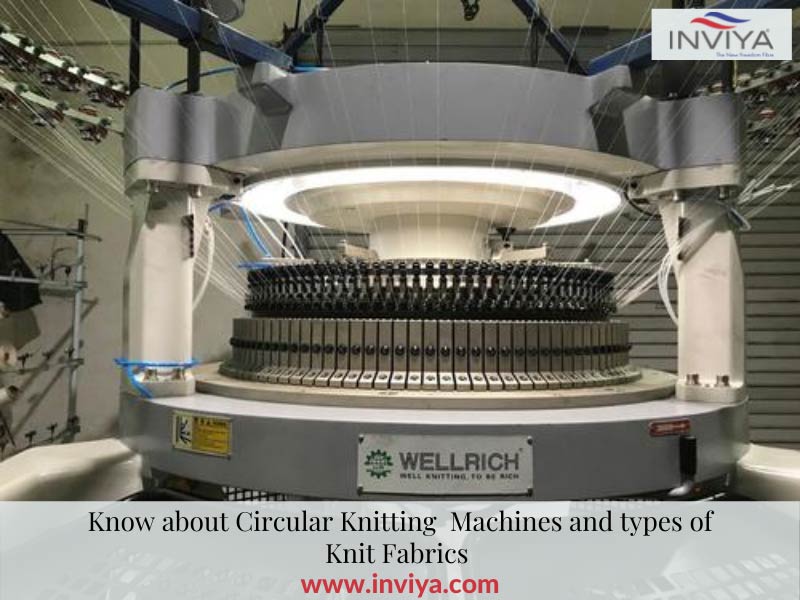

Circular knitting is a form of knitting that creates a seamless tube. The casting on stitches is done similarly as in flat knitting but the ends of that row of stitches are joined to form a circle.

Circular knitting, nowadays, is done by knitting machines. A double-bed machine, for example, can be set up to knit on its front bed in one direction and on its back bed on the return, which creates the complete tube. However, the knitting machines for sock-knitting use unique latch-hook needles to make each stitch in a round frame.

Advantages of Circular Knitting Machine

- Less load by higher precision

- Enhanced quality of plated fabric

- Extended needle life

- Less friction for each part

- Less Maintenance Cost

Different Types of Knitted Fabrics:

Depending on how the loops are made; two types of knitting are there:

- Weft knitted fabrics

- Warp knitted fabrics

1. Weft knitting

A fabric formation method in which the loops are made in a horizontal direction from a single yarn and the intermeshing of loops can take place both in a circular or flat form. The fabric formed by this method is very elastic, comfortable, and warm to wear.

Below are a few most-common Weft Knit Fabrics Structures:

Single jersey knit fabric

Single jersey is the most simplistic and reasonable weft structure to produce and is widely used for T-shirts, casual tops, hosiery, etc.

Weft knitted single jersey elastic fabrics are usually made by plating lycra (spandex) with cotton yarn in a circular knitting machine. This type of fabric and the material produced out of it have a great response and gain their original size and shape after physical extension. Lycra yarn possesses the capability to produce shapewear demanding large stretch and dimensional recovery that cannot be achieved by cotton yarn alone.

Features of Jersey Knit Fabric:

- Lightweight

- Less stretchy unless the material has spandex in it

- Visible right and wrong side of the fabric

- Edges curl up easily while pulling

Rib (double jersey) knit fabric

This type of fabric is produced by mesh wales of knit and purl stitch and is usually knitted with two sets of needles. The rib-knit fabric has an upright cord appearance making it twice as thick as plain knit with greater stability.

They can be produced either in a flat or circular knitting machine. The rib-knit is commonly used in the hemming and neckline of sweaters. Some other modifications of rib knit are Cable fabric, Bird’s eye, Cardigans, Milano’s ribs.

Features of Rib Knit Fabric:

- This fabric is heavier as compared to Jersey

- It is generally very stretchy among the 3 basic types of knit fabrics, however, the 1×1 rib is more stretchy than the 2×2 rib

- No notable distinction for the right and wrong side of the fabric

- It isn’t so smooth unlike Jersey knit

- The edges of rib-knit don’t curl up when pulled

Interlock knit fabric

This is a type of double-layered knitted structure designed by meshing knit and purl stitch in both wales on a knitting machine equipped with two sets of needles. The interlock knit resembles jersey knit on both front and back.

However, this fabric has greater dimensional stability than a single jersey and all other types of knitting and it does not curl up on edges. But, this fabric stretches more along the lengthwise direction than in breadthwise. The structure of the interlock knit fabric offers enhanced insulation as it is able to trap air between its layers. Such fabrics are most often used in the production of sweatshirts, table mats, etc.

Features of Interlock Knit Fabric:

- It is heavier and thicker than a jersey

- Interlock knit is not too stretchy as compared to Jersey

- This fabric is reversible, as there’s no right or wrong side

2. Warp knitting

This type of knitting is a method of fabric formation in which the loops are made along the length of the fabric in a vertical way and there is a needle for each yarn. The knitted stitches in these fabrics have a crisscross diagonal appearance that appears smoother than weft knitted fabrics.

Although warp knitting shows less elasticity than weft knitting, yet it becomes favorable over weft in properties like soft and drapey, higher density, warm to wear. Through the Warp Knitting process, various types of yarn can be prepared like combed, staple, carded and filament, which is not feasible with weft knitting.

Below are a few most-common Warp Knit Fabrics Structures:

The warp knitted fabrics are usually divided into three primary structures:

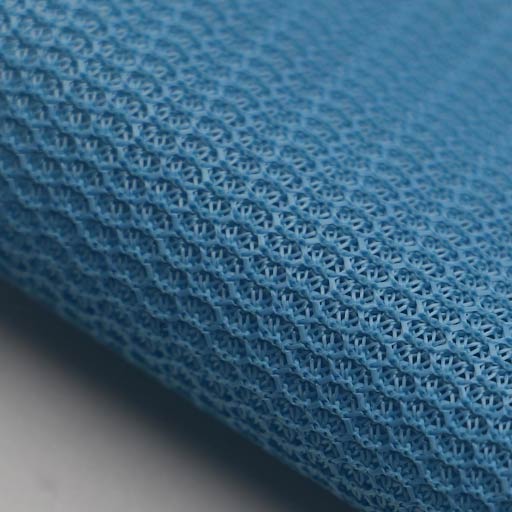

Tricot knits

This type of knitting leverages a single set of beard needles and thread yarns. The multifilament yarn face stitches are vertical to the backstitch, which offer a smooth surface with a thick stitch.

It gives good air/water permeability, softness, crease-resistance, drape; owing to its structure. Tricot knits are mostly used in lingerie, nightwear, dresses, etc.

Raschel knits

These knitted fabrics are made using a single set of latch needles and spun yarns. The knits can be lacy, deeply patterned, and even stacked. The properties of Raschel Knitted Fabrics comprise a fabric that can be dense or compact, open or lofty, stable or stretchy, single-faced or reversible.

These fabrics can be easily identified by their intricate designs and such fabrics can be used in almost any garment type due to the high customization of the raschel machine from lightweight lace to heavy chenille.

Milanese knit

This fabric is made up of two sets of yarns knitted diagonally. The face side has a fine vertical rib and the reverse has a diagonal structure. It is lightweight, drapey, smooth, and is mostly used for gloves.

Despite the above-mentioned basic types, there are numerous knitted fabrics made with various modifications. The flat or jersey knit can be modified by using different yarns or double-looped stitches of different lengths to make fabrics such as velour, terry, and plush.

Allied to it, there are also specialized weft knits available such as Intarsia, Fleece, Jacquard Jerseys, Knitted Velour, Knitted Terry, French Terry.